Hendry Hydraulic Cylinders

Navigation

Bespoke Cylinders - Manufactured To Your Exact Requirements

In addition to our standard ranges, we can also manufacture to your unique specifications, whether that’s a product from your own designs, or bespoke lines created by our in-house CAD team to suit your needs.

It’s this focus on flexibility and innovation that’s led to Hendry’s technical advances and innovations in applied hydraulics. Whatever the application, our experienced team will provide you with a product with quality and reliability built in.

We serve an ever-expanding list of clients in a diverse range of industries. You’ll find Hendry Hydraulic cylinders in the construction, oil and gas, automotive, agricultural, environmental, mining, forestry, access work platforms and material handling sectors. This wide range of experience means that we understand your needs and applications.

Information Required When Enquiring / Ordering

To provide our team with the best information to design the right cylinder for you, the following details are important to have when ordering or enquiring about a cylinder.

Send us your requirements today through our products enquiry form.

1. Single or Double Acting

A single-acting cylinder is a cylinder in which the working fluid acts on one side of the piston only. A single-acting cylinder relies on the load, gravity, or springs to push the piston back in the other direction.

A double-acting cylinder is a cylinder in which the working fluid acts alternately on both sides of the piston. In order to connect the piston in a double-acting cylinder to an external mechanism, a hole must be provided in one end of the cylinder for the piston rod and this is fitted with a gland to prevent escape of the working fluid.

2. Application that the cylinder is required for.

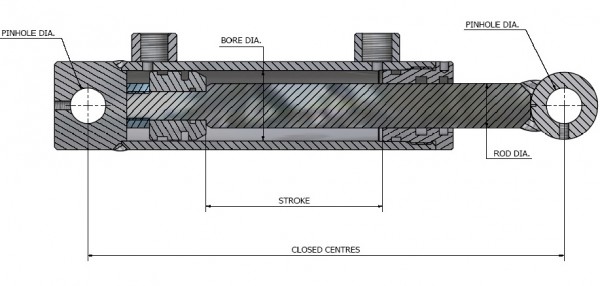

3. Stroke

This is the actual travel of the cylinder; Extended length (pin-to-pin centers) minus the retracted length (pin-to-pin center)

4. Closed Centres

This is the length, pin center to pin center, when the cylinder is fully closed.

5. Rod Diameter

This is the diameter of the piston INSIDE the cylinder tube.

6. Bore Size of Tube

The diameter of the inner tube. The larger the bore, the more lifting force.

7. Pin Hole Sizes

8. Size of Oil Supply Ports

9. Mounting Option Required

Click the link to see examples of the types of mountings offered.

Send us your requirements today through our products enquiry form.